How To Install A Flanged Window

After framing and covering, in that location is no step more basic to edifice a house than installing windows. Most windows today take an integral attachment flange, so this article volition focus on that blazon of window. In 2016, JLC published two articles by Gene Summy, a contractor and edifice inspector from Laguna Niguel, Calif., that addressed ii different approaches to installing flanged windows (see "Installing Flanged Windows: Two Strategies Compared," Jan/16, and "Installing Flanged Windows Function 2," Apr/sixteen). Those articles contain much greater detail about subsequent sealing and testing, and we encourage folks to read them for more information. Our goal hither is to present streamlined versions of the two strategies next for readers to evaluate and cull betwixt.

Click to enlarge

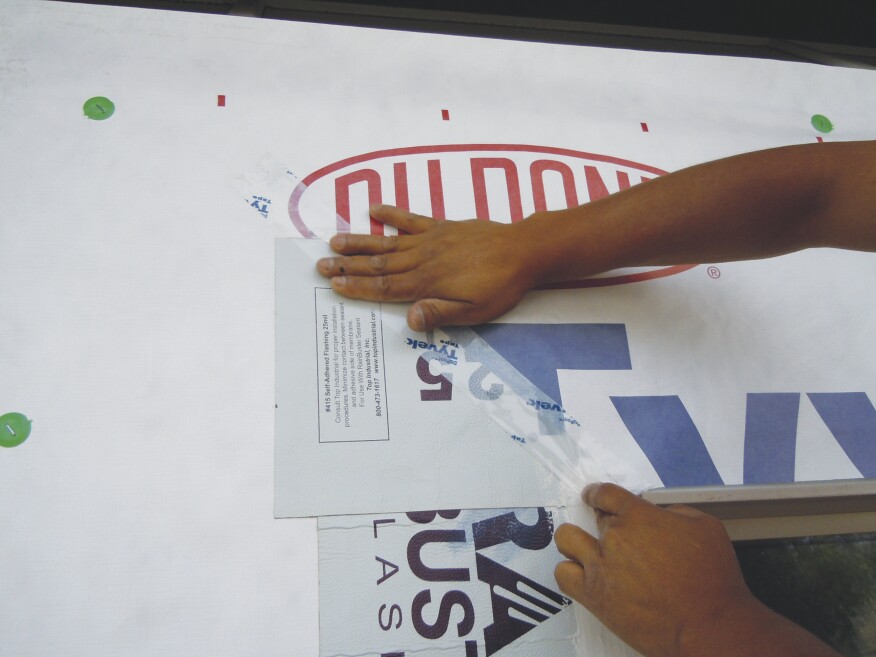

Both installation methods depend on a combination of self-adhered flashing tape (SAF) and sealant. SAF comes in many different configurations from many unlike manufacturers. Regardless of the type of SAF that is used, the installer should always get over the tape with a J-roller or similar tool to ensure total adhesion.

Properly applied sealant too plays an indispensable role in window installation, and selecting the right sealant is important. Window manufacturers use a variety of materials for the window cladding and flanges, and some sealants may non be compatible with certain windows. Always follow the manufacturer's specific sealant recommendations to avoid an agin reaction between the sealant and the flange material.

Click to overstate

Method 1 (above) is commonly associated with East Declension installers. After prepping the opening, the installer applies a dewdrop of sealant either to the back of the outside edge of the window flange or directly on top of the WRB, leaving broad drainage gaps along the bottom border. If the latter strategy is called, it helps to get-go dry out fit the window and draw a line around the perimeter of the window flange. The bead of sealant should go but inside that line. Press the window into place and make sure it is level and square, fasten the corners with truss-head screws or roofing nails, and confirm that the window operates properly. Drive fasteners in the remaining holes and smooth out excess sealant that has oozed from the flange. When sealant has cured, apply SAF to the sides of the window and then across the top of the window. Next, fold the WRB flap downwards and seal the corners. The advantage to this method is that the SAF seals directly to the window flange so y'all aren't depending on sealant lone to keep water out.

Click to enlarge

Method two (above) is usually associated with Due west Coast installers. Subsequently prepping the opening, the installer applies SAF to both sides of the opening, and a bead of sealant either to the dorsum of the outside edge of the window flange or direct on top of the SAF. If you're applying caulk to the SAF, it helps to first dry fit the window and depict a line effectually the perimeter of the window flange; the bead of sealant should go but inside that line. Remember to get out broad gaps along the bottom. Press the window into identify and make sure it is level and square, fasten the corners with truss-head screws or roofing nails, and ostend that the window operates properly. Drive fasteners in the remaining holes and polish out excess sealant that has oozed from the flange. When sealant has cured, apply SAF across the top of the window. Then fold the WRB flap down and seal the corners. The advantage to this method is that it allows for quick inspection of the sealant coverage without disturbing the SAF should a leak be discovered.

Source: https://www.jlconline.com/training-the-trades/installing-flanged-windows_o

Posted by: blacksaight.blogspot.com

0 Response to "How To Install A Flanged Window"

Post a Comment